#

03-20 Wheel Retorque

Read and follow the outlined instructions when installing or servicing the hub. Improper installation could result in property damage, injury, or death.

Re-torque all wheel nuts after 50 to 100 miles of service on the initial "in-service" following any installation of the wheel to hub assembly.

WHEEL ASSEMBLY PROCEDURE

This vehicle is equipped with hub-piloted disc wheels, flange nuts and M22 x 1.5 studs.

1. Clean all mating surfaces on hub, drum, wheels and nuts.

2. Rotate hub so a pilot boss is at the top (12 o'clock) position.

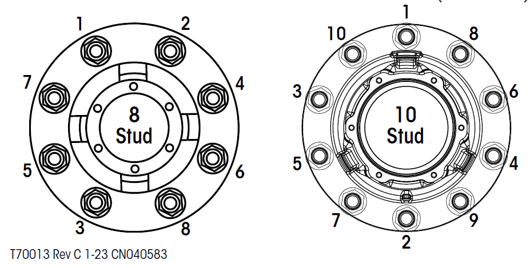

3. Mount brake drum on hub so it seats on drum pilot and against hub face.

4. Mount wheel(s) on hub. Wheel nuts can be started in order to hold wheel and drum into position. Use of plastic wheel spacers (guards) is not recommended by Hendrickson.

5. If using two-piece flange nut, apply one drop of SAE 30W motor oil on the first two or three threads of the stud and apply two drops between the flange and the nut.

6. Snug top (12 o'clock) and bottom (6 o'clock) wheel nuts and apply 50 ft. lbs. (68 Nm) of torque to draw wheel and brake drum fully against the hub.

7. Inspect to ensure proper assembly with wheel and brake drum positioned on pilot bosses before installing remaining wheel nuts.

8. Using sequence shown on left, tighten all wheel nuts to 50 ft. lbs. (68 Nm) of torque.

9. Repeating sequence, retighten all wheel nuts to a final torque of 475±25 ft. lbs. (645±30 Nm).

10. Check seating of wheel and brake drum at the pilot bosses. Rotate wheel and check for any rotational irregularity.